Setting up a single semiconductor manufacturing foundry requires massive investments, usually running up to $3 to $4 billion. To compare it with current investments, Micron is pumping in $825 million to set up its packaging facility.

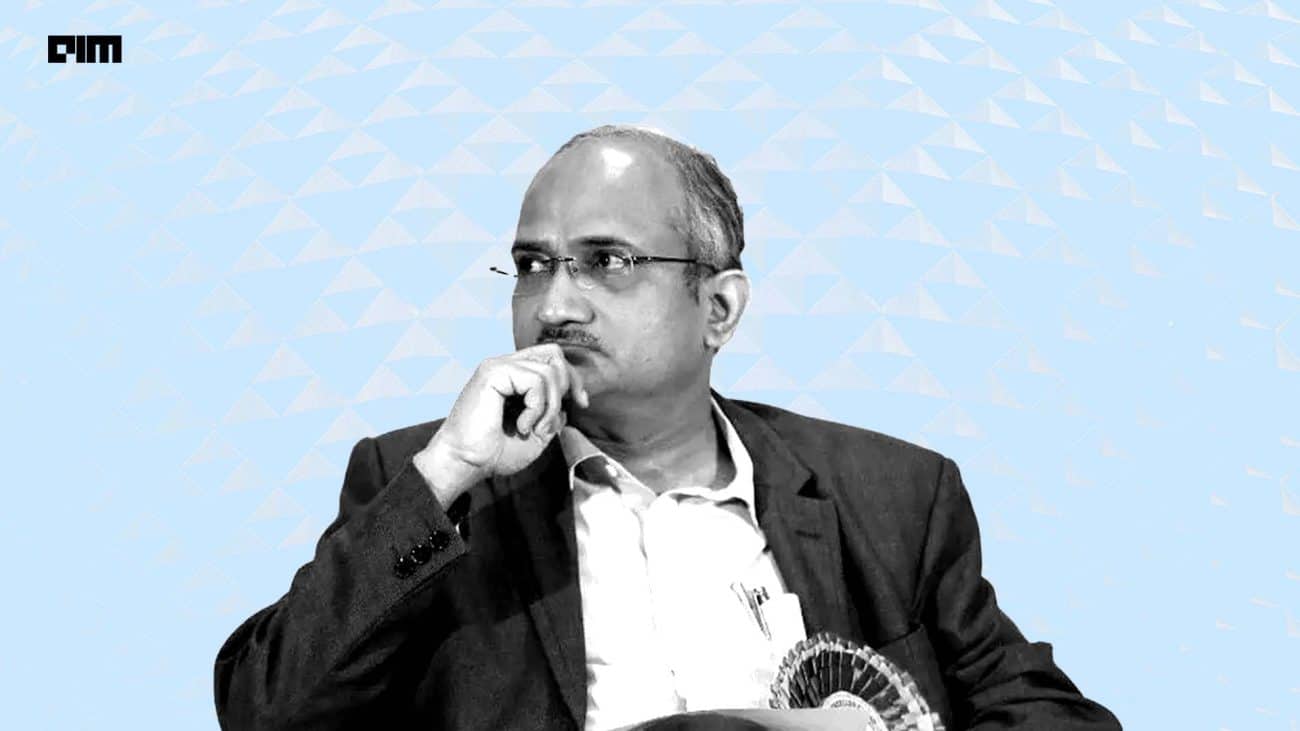

“Given our infrastructure and the lack of ecosystem for semiconductor supplies, companies hesitate to venture into this field in India. A semiconductor foundry also requires many auxiliary industries such as semiconductor grade gases and chemical supplies, which are not present in India” said BITS Pilani Campuses group vice-chancellor Professor V Ramgopal Rao, in an interview with AIM.

The Indian government has been very clear and focussed about its semiconductor mission, which was launched in 2021. Currently, India is the second largest importer of semiconductor chips globally after a 92% increase in chip imports in the last three years.

Rao said that investing so much in a country where the infrastructure is not up to the global standards is a challenge for big companies.

India is all About Manpower

Many companies from the Global North look to India as a source of “affordable talent”. This is where the problem lies. According to Rao, the semiconductor industry does not require as many employees to work as India has on offer. Companies come here to set up plants that require massive manpower, which is India’s advantage.

“A full-fledged foundry with 50,000 wafers per month processing capability will hire only about 1,500 employees,” he said. Some jobs will however be created in the auxiliary sectors. Such small numbers, he elaborated, compounded with the missing infrastructure, do not attract the investments needed. In comparison, Malaysia, Singapore, and Taiwan have a flourishing ecosystem for such semiconductor foundries and are seen as better options.

Though there are a number of designing and manufacturing companies in India, there is no foundry. Despite several semiconductor startups present in Bengaluru, manufacturing still happens in other countries. The present government is making significant efforts to woo the semiconductor players with massive subsidies. These subsidies can easily go to over 50%, Rao said. Increasing interest from semiconductor companies and joint partnerships with Indian companies may eventually help India achieve its target of capturing 10% of the world’s semiconductor market by 2030. “For design, India is already a global powerhouse”. Rao said.

To put this into context, Mindgrove Technologies, a fabless semiconductor startup supported by Peak XV Partners, recently unveiled India’s inaugural commercial high-performance SoC (system on chip) dubbed Secure IoT.

Rao emphasised on involving the academia in such missions for boosting the innovation ecosystem. He gave the example of the automotive industry, saying even though India is one of the major players exporting components to several countries in the industry, there is not much innovation happening in the country. “Does India have any cars that others don’t?” asked Rao, saying that the cars that India builds are replicas of what’s available elsewhere.

On the other hand, Rao believes that the reason India hasn’t built something like a Tesla is because of a lack of collaboration with academia. Despite a thriving automotive industry, “Nobody wants to take mechanical engineering or study other automotive subjects in the country because there aren’t any decent paying jobs. This is a result of lack of innovation and lack of collaborations between industry and academia,” said Rao.

Coincidentally, in a similar post on X where a user said that India cannot compete with Japanese or American cars, Mahindra Group chairman Anand Mahindra thanked the person for the scepticism.

“We were told the same thing when Toyota and other global giants in the UV space entered India. But we’re still around. Every day is a fight for survival,” he said while acknowledging that there needs to be more innovation and investment in the automotive industry.

Even when companies want to build a technology, they choose to partner with companies outside India and do not focus on academic partnerships. The same is the case with the semiconductor industry. “Companies want to come to India still for cutting costs because of abundant supply of talent, but it’s time they come to India for tapping into India’s innovation capabilities, ” said Rao.

Meanwhile, there is also a rise in semiconductor GCCs in India, which accounted for 30% of the GCCs set up in Q4 2023.

Need for Industry-Academia Collaboration

As Rao mentioned, there is a significant lack of collaboration between academia and industry, hampering the innovation potential across sectors. “The future lies in connecting academia with industry, which will enable India to lead in markets like sensors and IoT,” he said. India currently ranks 66th among 130 countries for Academia-industry collaborations, which is where the problem lies.

Although there is considerable research happening in academia, it isn’t being utilised for developing products for meeting the Indian needs, be it in agriculture, healthcare, security. Additionally, students are not industry-ready because industries aren’t collaborating with academia.

Industry involvement is the key, whether it’s to make our students industry ready or to reap the benefits of research happening in the country. Industry involvement is needed to convert research into innovation.

“When it comes to semiconductor jobs today, there’s a significant gap in supply and demand in India. While there is a demand for design specialists, there are fewer opportunities in fabrication and technology areas,” Rao added. Consequently, many students specialising in Semiconductor Technology related areas end up working abroad.

Similar to the semiconductor industry, the development of AI is also slow for similar reasons, namely a lack of investment in research and development. “India’s research spending is insufficient to support innovation in high-tech areas like AI. We rank 56th among 130 countries when it comes % GDP spends on research. We need to spend at least 3 X more to catch up with the developed world,” he added. We need more schemes for co-funding by industry alongside the government.

“It took OpenAI tens of billions of dollars to make ChatGPT. The research funding in India is so tiny,” Rao added. For AI, there is a dire need for a massive number of GPUs. Indian universities barely have the necessary infrastructure for AI research. Meanwhile, the total amount of research funding that Indian universities receive, China spends on just two universities.

The bureaucratic hurdles in spending allocated funds make it challenging for researchers to utilise the money effectively, leading to further cuts in research spending. “The next government looks at the last budget and actual utilisation and adds some 5% to that, but the base is already very low,” Rao explained.

Researchers have massive hopes on the INR 6000 crore that the Indian government had allocated for quantum computing research. “There have been substantial delays. In these deep-tech areas, speed of execution is critical. Against the last call, close to 400 proposals have been received. There is excitement all around,” said Rao.

The government’s hesitation to invest more in research is due to the low base of research spending, coupled with bureaucratic hurdles in spending allocated funds. This vicious circle hampers innovation and research in India, but unfortunately, it’s a topic that receives little attention. Ease of doing research, is something that needs to be carefully evaluated for these funding schemes to be effective, Rao added.